How to Guide

Will my hand activate the chain brake during each time kickback happens?

No, it won’t. In order to move the hand guard forward there is certain force needed, if your hand doesn’t move it hard enough or slips over it, the chain brake won’t be activated. Firm grip should always be kept. Also in certain positions hand cannot reach the front hand guard to activate the chain brake like when the saw chain is held in felling position

Will inertia activate chain brake each time kickback occurs?

No, it won’t. In order for inertia activating the chain brake the kick back force needs to be high enough, otherwise chain brake would be activated very often and chainsaw normal operation would be very little.

Will my chain brake each time protect me from kickback caused injury?

No, it won’t. In order for chain brake to activate it needs to be strong enough and the bar mustn’t be to close to you. Only proper working technique can minimize or/and eliminate kickbacks.

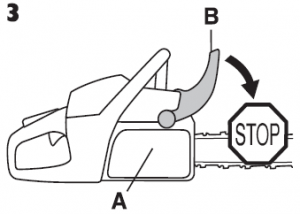

How does the throttle lockout work?

The throttle lockout is built in to prevent not wanted operation of the throttle control. When you grasp the handle you press the lock (A) and it activates the throttle control (B) as shown on the picture number 3 Once handle is released the throttle control and the throttle lockout go back to their original positions

How does the chain catcher work?

The chain catcher is built to catch the chain when it jumps off or snaps. When chain is properly tensioned it should never happen.

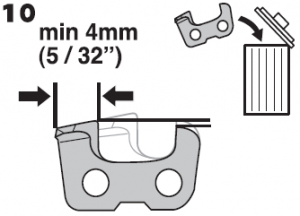

How will you know that the chain should be replaced?

The cutting equipment condition should be checked daily. Any signs of stiff chain, visible cracks in rivets and links, rivets and links are badly worn are immediate indication for chain replacement. Chain also always needs to be replaced when the length of the cutting teeth is lower or close to 4 mm as shown on the picture number 10

What is the purpose of the right hand guard?

The right hand guard stops twigs and branches from interfering with your grip on the rear handle and protects your hand if the chain jumps or snaps.

What vibration damping system is for?

The vibration damping system is built to make operation easier and minimize vibration .The vibration damping system minimalizes the transfer of vibration between the machine′s handle unit and the engine unit/cutting equipment. Remember that cutting with blunt chain will increase vibration level significantly. Overexposure to vibration can lead to damage in never or circulatory systems

What stop switch is being used for?

Use the stop switch to switch off the engine

What muffler is being used for?

The muffler is built to lower noise levels and to direct exhaust fumes away from the user

How to properly sharpen cutting teeth?

In instances when the chain is blunt you need to exert more pressure to force the bar through the wood and the chips will be very small. If the chain is very blunt it will produce wood powder and no chips or shavings. A sharp chain easily goes through the wood and leaves thick, long, chips. Whenever sharpening the tooth you need to pay special attention to following: file position, filing angle, round file diameter and cutting angle. Always use proper sharpening equipment

To sharpen cutting teeth use a file gauge round file. Switch off the engine as shown on the picture number 29.

Verify if chain is well tensioned. Reduce the pressure on the return stroke. File cutting teeth from the inside face. File all the teeth on one side first, then turn the chain saw over and file the teeth on the other side. File all the teeth to the same length. During sharpening the file must be positioned so as determine the following three corners of the cutting: “A” upper angle 30° – 35° “B” external side angle 85° – 90° “C” internal side angle 60° 2. The file must be positioned and must work perpendicularly to the bar. In order to achieve very precise side angles position the file so that you vertically cross over the cutting edge of about 0,5 mm. Sharpen all the teeth of one side first then turn the saw over and repeat the operation. To obtain a uniform cutting surface in the wood, all the teeth must be sharpened to the same length. Pay attention not to reduce the size of the cutting teeth below 4 mm, if that is your case you need to replace the chain with a new one.

How to verify that my chain is well tensioned?

Place the chain on the bar and stretch it using the chain tensioner and checking that the chain has the correct tension and that it’s blocked with the safety brake

How to adjust the depth gauge?

The cutting teeth needs to happen beforeyou start to adjusting setting of the depth gauge. Every third sharpening the cut teeth the depth gauge setting adjustment should happen. You will need a flat file and a depth gauge tool. We recommend that you use our depth gauge tool to achieve proper setting of the depth gauge. Place the gauge depth tool over the chain. The flat file should be used to file off the depth gauge tip that goes through the tool. The depth gauge setting is correct when you no longer feel resistance as you draw the file along the depth gauge

How to lubricate my chainsaw?

You should lubricate your chainsaw with a good chain oil for both safety and comfort needs. McCulloch recommends universal vegetable biodegradable oil for outdoor chains- there is one McCulloch is producing. In instances when the universal outdoor accessories chain oil is not available, standard chain oil is recommended.

What petrol should I use for my chainsaw?

Good quality leaded or unleaded petrol should be used with the 90 octane grade. In instances when you run the engine on a lower octane knocking risk is much higher. In instances when you work on non stop high revs you should use a higher than 90 octane petrol

What oil should I use for my chainsaw?

McCulloch chainsaws require two-stroke universal outdoor oil. Mixing ratio should be (3%) 1:33 with oils class ISO or JASO formulated for air-cooled, two-stroke engines and (2%) 1:50 with Universal Outdoor Accessories two-stroke oil.

How should I transport and store my McCulloch chainsaw?

McCulloch chainsaws as same as all other brands chainsaws should be when stored for a longer period of time need to be emptied from fuel- that should be placed in separate container. The same rule should be followed when chainsaw is transported. What’s more the guide bar cover must be placed on the cutting parts of the chainsaw and the spark plug cap should be removed from the spark plug. The chain brake should be activated. Chainsaw needs to be secured when transported. Complete service should be done out before long-term storage

How to stop my chainsaw?

In order to stop the engine push the stop switch down. Remember that the stop switch automatically return to run position. If you don’t want your chainsaw to start always remove the spark plug cap must from the spark plug

How to extend life-cycle of my chainsaw?

How to check the brake trigger?

In order to check the brake you need to put the chain saw on firm ground. Start the chainsaw and push for full throttle. Afterwards start the chain brake. Never let the front handle go. The chain saw brake should activate immediately

How to check Mc Culloch chainsaw oil level?

In McCulloch chainsaws fuel runs out before the saw chain oil, whenever there is enough fuel and chain oil the the tanks. Chain lubrication should also be verified each time you refuel. The tip of the bar should be aimed at a light coloured surface around 20 cm away. 1 minute later you should run your chainsaw at 3/4 throttle and then you see light line of oil on the light surface. If that is not the case you will need to verify if there is no obstruction at the oil channel present in the bar, alternatively you will need to verify that the edge of the bar is clean. When after cleaning all mentioned before chainsaw is still not working properly you should take your equipment into the nearest McCulloch service station.

How to fit a spike bumper?

The spike bumper is factory fitted on most McCulloch chainsaws and should be replaced only in the servicing stations.